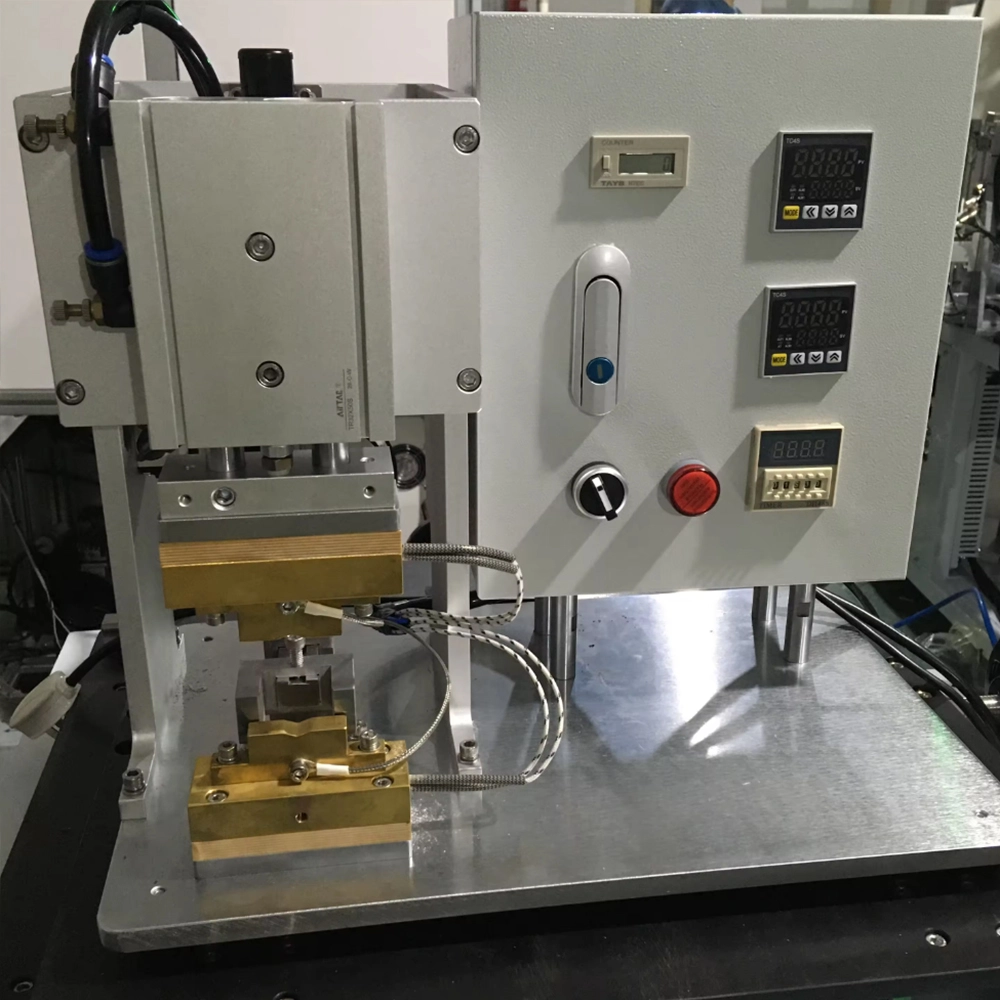

Stand Up Pouch Filling And Sealing Machine

Stand-up pouch filling and sealing machines come in various sizes to accommodate different production capacities and packaging requirements.

Custom Parameters

Stand-up pouch filling and sealing machines come in various sizes to accommodate different production capacities and packaging requirements. The size of a stand-up pouch filling and sealing machine is typically determined by factors such as the pouch dimensions, filling volume, sealing speed, and overall footprint. Here are some common sizes of stand-up pouch filling and sealing machines:

▪ Tabletop Machines: Tabletop stand-up pouch filling and sealing machines are compact and portable, designed for small-scale or low-volume production. They are suitable for startups, small businesses, or laboratories that require flexibility and space-saving equipment. Tabletop machines can handle pouch sizes ranging from small sachets to medium-sized stand-up pouches and have lower production capacities compared to larger machines.

▪ Medium-sized Machines: Medium-sized stand-up pouch filling and sealing machines are designed for moderate production volumes and offer increased throughput compared to tabletop models. They typically have a larger footprint and can handle a wider range of pouch sizes, filling volumes, and sealing speeds. Medium-sized machines are suitable for small to medium-sized businesses or production facilities with moderate packaging demands.

▪ High-speed machines: high-speed stand-up pouch filling and sealing machines are large-scale production systems capable of handling high volumes of pouches with rapid filling and sealing cycles. These machines are equipped with advanced automation, servo-driven technology, and multiple filling stations to maximize efficiency and productivity. High-speed machines are ideal for large-scale manufacturing operations, contract packers, or industries with high-demand packaging requirements.

▪ Customized Solutions: Some manufacturers offer customized stand-up pouch filling and sealing machines tailored to specific packaging applications, production requirements, and pouch sizes. These custom solutions may include multi-lane machines for high-speed production, integrated systems for filling multiple products into one pouch, or specialized equipment for unique pouch shapes or materials.

The size of a stand-up pouch filling and sealing machine can vary based on the specific needs and preferences of the manufacturer or packager. Factors such as production volume, pouch size, filling technology, and budget considerations play a crucial role in determining the most suitable machine size for a given application. Additionally, manufacturers may offer modular designs or upgrade options to accommodate future growth or changing production needs.

Product Features

Stand-up pouch filling and sealing machines are equipped with a variety of features designed to optimize efficiency, accuracy, and reliability in the packaging process. Here are some features commonly found in stand-up pouch filling and sealing machines:

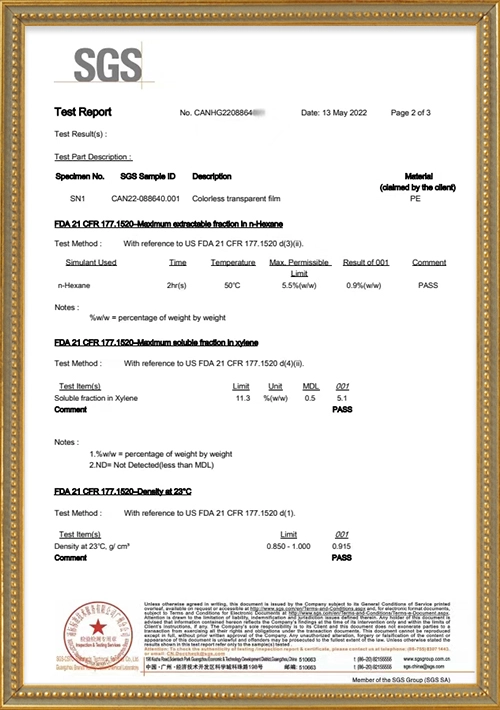

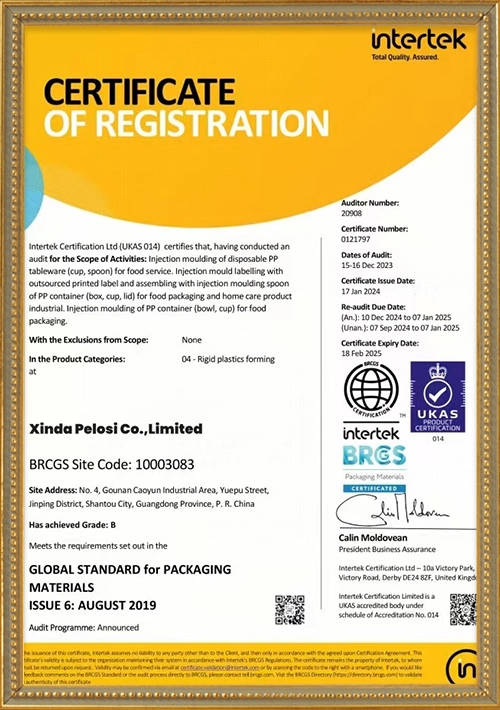

Our Certificates

We adhere to the highest industry standards and have obtained global certifications such as SGS and intertek, consolidating our commitment to quality and safety while adapting to different regulations in the global market.

Get a quote with Xinda pelosi

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

Your inquiries, ideas, and collaboration opportunities are just a click away. Let's start the conversation.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

You may also like

We provide a variety of packaging solutions to both small and large businesses and service numerous industries, including beauty and personal care, food and beverage, household and industrial chemicals, and veterinary care.

Scan QR Code

Scan QR Code

Whatsapp: +8613640286461