Customized Stand Up Pouch Filling And Sealing Machine to Suit Your Requirements

The features of stand-up pouch filling and sealing machines are designed to optimize productivity, quality, and versatility in the packaging of various products, ranging from food and beverages to pharmaceuticals and industrial goods. These machines offer advanced automation, precision, and control to meet the demands of modern packaging operations. The advantages of stand-up pouch filling and sealing machines make them an essential asset for manufacturers looking to optimize their packaging operations, improve product quality, and gain a competitive edge in the marketplace.

Why Choose Xinda Pelosi's Stand Up Pouch Filling And Sealing Machine?

Stand-up pouch filling and sealing machines offer numerous advantages over traditional packaging methods, making them a preferred choice for many manufacturers. Here are some advantages to stand-up pouch filling and sealing machines:

Stand Up Pouch Filling And Sealing Machine Application Scenarios

Stand-up pouch filling and sealing machines are versatile packaging solutions that find applications across various industries due to their efficiency, flexibility, and reliability. Here are some common applications of stand-up pouch filling and sealing machines:

Food and Beverage Industry

Stand-up pouch filling and sealing machines are widely used for packaging a variety of food and beverage products, including:

▪ Sauces and condiments (e.g., ketchup, mayonnaise, salad dressing)

▪ Liquid and semi-liquid products (e.g., soups, broths, juices, smoothies)

▪ Snack foods (e.g., nuts, dried fruits, granola)

▪ Ready-to-eat meals and meal components (e.g., pasta sauces, curry sauces, gravies)

▪ Dairy products (e.g., yogurt, pudding, dessert mixes)

Pharmaceutical and Healthcare Products

Stand-up pouch filling and sealing machines are utilized for packaging pharmaceuticals, medical devices, and healthcare products, including:

▪ Liquid medications (e.g., syrups, oral suspensions, cough syrups)

▪ Nutritional supplements (e.g., protein powders, vitamin gummies, energy drinks)

▪ Topical creams and ointments (e.g., lotions, gels, creams)

▪ Diagnostic reagents and test kits

▪ Medical disposables and accessories (e.g., saline solutions, wound care products)

Personal Care and Cosmetics:

Stand-up pouch filling and sealing machines are employed for packaging personal care and cosmetic products, including:

▪ Shampoos and conditioners

▪ Body washes and shower gels

▪ Lotions, creams, and moisturizers

▪ Hair care products (e.g., serums, masks, treatments)

▪ Sunscreen and tanning lotions

Household and Cleaning Products

Stand-up pouch filling and sealing machines are used for packaging household and cleaning products, including:

▪ Laundry detergents and fabric softeners

▪ Dishwashing liquids and detergents

▪ Surface cleaners and disinfectants

▪ Air fresheners and deodorizers

▪ Automotive fluids and lubricants

Pet Care Products

Stand-up pouch filling and sealing machines are employed for packaging pet food, treats, and care products, including:

▪ Dry and wet pet food

▪ Pet treats and snacks

▪ Pet supplements and vitamins

▪ Pet shampoos and grooming products

Industrial and Chemical Products

Stand-up pouch filling and sealing machines are utilized for packaging industrial and chemical products, including:

▪ Lubricants and oils

▪ Adhesives and sealants

▪ Paints and coatings

▪ Agricultural chemicals and fertilizers

▪ Automotive fluids and additives

Retail and Convenience Products

Stand-up pouch filling and sealing machines are used for packaging various retail and convenience products, including:

▪ Single-serve snacks and beverages

▪ Travel-sized toiletries and personal care items

▪ On-the-go meal kits and snack packs

▪ Specialty and gourmet food products

▪ Promotional and sample packs

Use Safe Materials for Custom Stand Up Pouch Filling And Sealing Machine

Stand-up pouch filling and sealing machines are constructed using various materials to ensure durability, reliability, and hygiene in packaging operations. The materials used in the construction of these machines are selected based on their compatibility with food-grade standards, resistance to corrosion, and ability to withstand high-speed production processes. Here are the primary materials commonly employed in stand-up pouch filling and sealing machines:

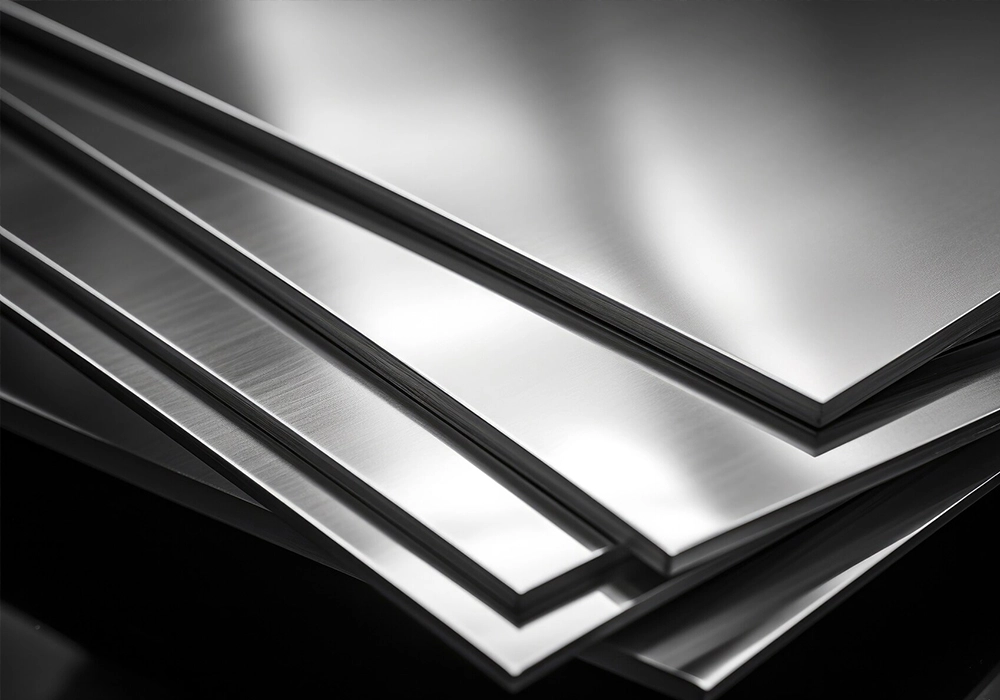

Stainless Steel:

Stainless steel is a preferred material for the frame, structure, and components of stand-up pouch filling and sealing machines. It offers excellent corrosion resistance, durability, and easy cleanability, making it ideal for use in food and beverage packaging applications where hygiene is paramount. Stainless steel is also suitable for contact with food products, ensuring compliance with food safety regulations.

Aluminum Alloy:

Aluminum alloy is used in the construction of certain components and parts of stand-up pouch filling and sealing machines, such as the sealing bars, heat plates, and guides. Aluminum alloy provides lightweight, thermal conductivity, and resistance to wear and tear, contributing to the efficient and precise operation of the machine.

Plastic Components:

Certain non-metallic components of stand-up pouch filling and sealing machines may be made from high-quality engineering plastics such as polyethylene (PE), polypropylene (PP), or polytetrafluoroethylene (PTFE). These plastics offer chemical resistance, low friction, and dimensional stability, ensuring smooth and reliable performance of moving parts, guides, and seals within the machine.

Rubber and Silicone:

Rubber and silicone materials are used for gaskets, seals, and O-rings in stand-up pouch filling and sealing machines. These materials provide flexibility, elasticity, and resistance to heat and chemicals, ensuring airtight seals and preventing leakage during the filling and sealing process.

Composite Materials:

Some specialized components of stand-up pouch filling and sealing machines may incorporate composite materials such as carbon fiber or fiberglass-reinforced plastics. These materials offer high strength-to-weight ratios, stiffness, and resistance to fatigue, enhancing the performance and longevity of critical machine parts subjected to high stress or repetitive motions.

Overall, the materials used in stand-up pouch filling and sealing machines are selected to meet the stringent requirements of food packaging operations, ensuring product safety, efficiency, and compliance with regulatory standards. Stainless steel, aluminum alloy, plastics, rubber, and composite materials are carefully chosen to optimize machine performance, durability, and hygiene in the packaging industry.

More Stand Up Pouch Filling And Sealing Machine

Get a quote for free

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly. Your inquiries, ideas, and collaboration opportunities are just a click away. Let's start the conversation.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

Scan QR Code

Scan QR Code

Whatsapp: +8613640286461